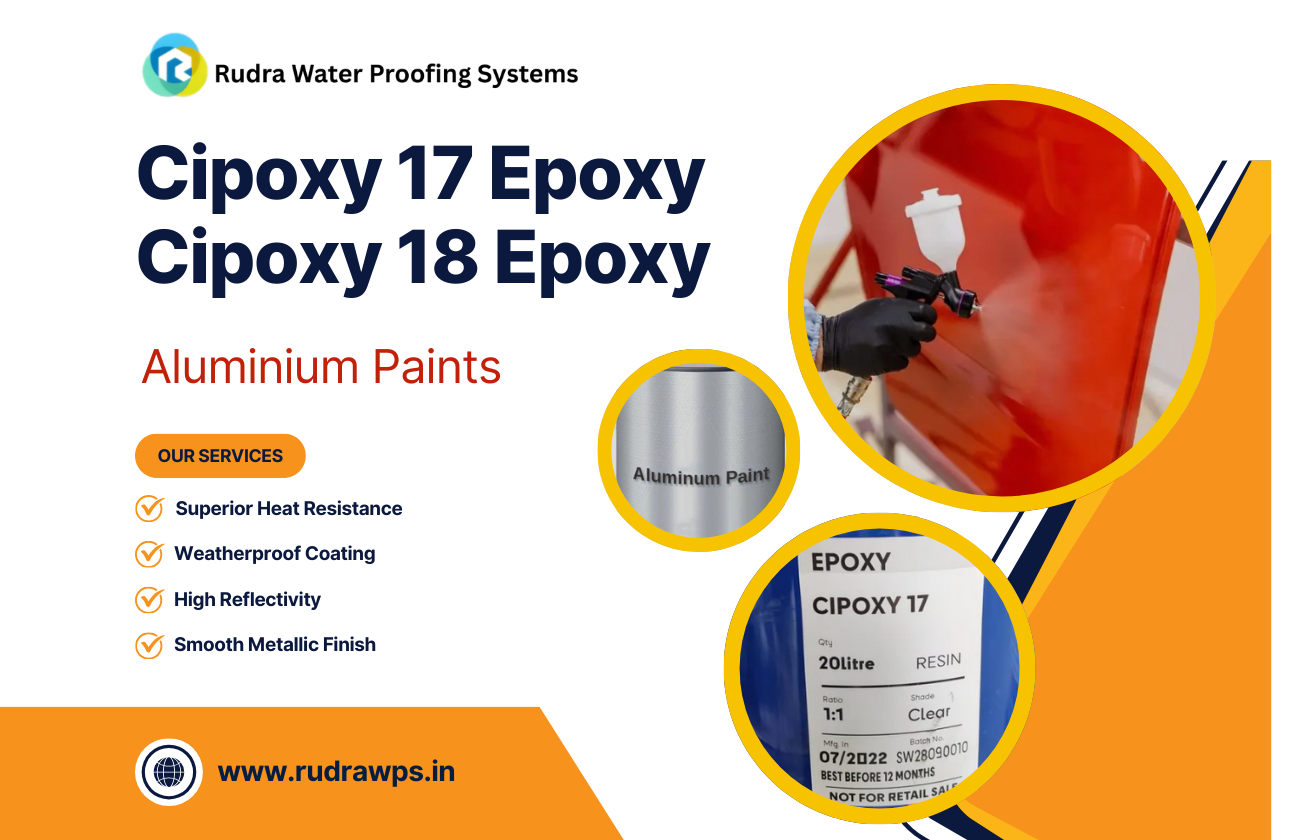

Unlocking the Potentials: Cipoxy 17 Epoxy, Cipoxy 18 Epoxy, and Aluminium Paints

In the world of protective coatings, choosing the right materials can make a world of difference in terms of longevity and performance. This is where products like Cipoxy 17 Epoxy, Cipoxy 18 Epoxy, and aluminium paints come into play. Each contributes uniquely to the durability and aesthetics of coated surfaces, making them popular choices across various industries.

Cipoxy 17 Epoxy: A Foundation for Durability

Cipoxy 17 Epoxy is renowned for its robust adhesion properties and high resistance to environmental and chemical elements. This type of epoxy is ideal for creating a durable barrier that protects structures from moisture and chemical aggression. Its application ranges from industrial machinery to marine environments where high performance is a must.

The versatility of Cipoxy 17 Epoxy allows it to suit numerous substrate applications ensuring enhanced longevity and reliability. This product is particularly beneficial in scenarios where the coated structures are subjected to extreme conditions or require frequent maintenance-free service.

Cipoxy 18 Epoxy: Elevated Protection

Similarly, Cipoxy 18 Epoxy takes protection to the next level by offering increased resistance against high impact and abrasion. It is specifically designed for environments where mechanical stresses and chemical exposures are routine. The innovation behind Cipoxy 18 lies in its formulation, providing unparalleled protection and extending the lifecycle of assets.

Whether for infrastructure, manufacturing facilities, or specialized equipment, Cipoxy 18 Epoxy serves as a reliable ally in maintaining the integrity and value of investments.

The Role of Aluminium Paints

Complementing the Epoxy coatings, aluminium paints offer exceptional protective qualities through reflective properties. They excel in reducing heat transfer and are highly effective in preventing corrosion and UV damage. Aluminium paints are often touted for their aesthetic appeal, providing a sleek finish that also serves as a functional protector for metallic surfaces.

These paints are commonly used in automotive, aerospace, and industrial applications due to their strong protective capabilities and ability to enhance the lifespan of metallic surfaces.

Choosing the Right Coating Solution

Selecting between Cipoxy 17, Cipoxy 18, and aluminium paints often depends on the specific requirements of the projects. Factors such as environmental exposure, mechanical demands, and desired durability metrics should all play a role in the decision-making process. Collaborating with a specialist can help ensure that the chosen product meets all operational needs and performance expectations.

Conclusion

Cipoxy 17 Epoxy, Cipoxy 18 Epoxy, and aluminium paints provide powerful solutions for industries seeking reliable and high-performance coatings. Understanding the unique benefits of each and their ideal applications will empower businesses to make informed decisions that uphold quality and enduring performance.

For more insights on the best coating practices and product options, stay tuned to our blog where we delve deeper into the science of protective coatings and their applications.

Published on December 24, 2025 by Admin