The Backbone of Every Industry Lies Beneath Its Floor

In the world of heavy-duty operations and high-performance facilities, the quality of your floor plays a crucial role in safety, efficiency, and aesthetics. Industrial floors are constantly exposed to mechanical wear, chemical spills, and high traffic — conditions that demand a surface built to last.

That’s where Industrial Epoxy Floor Coating Services come in.

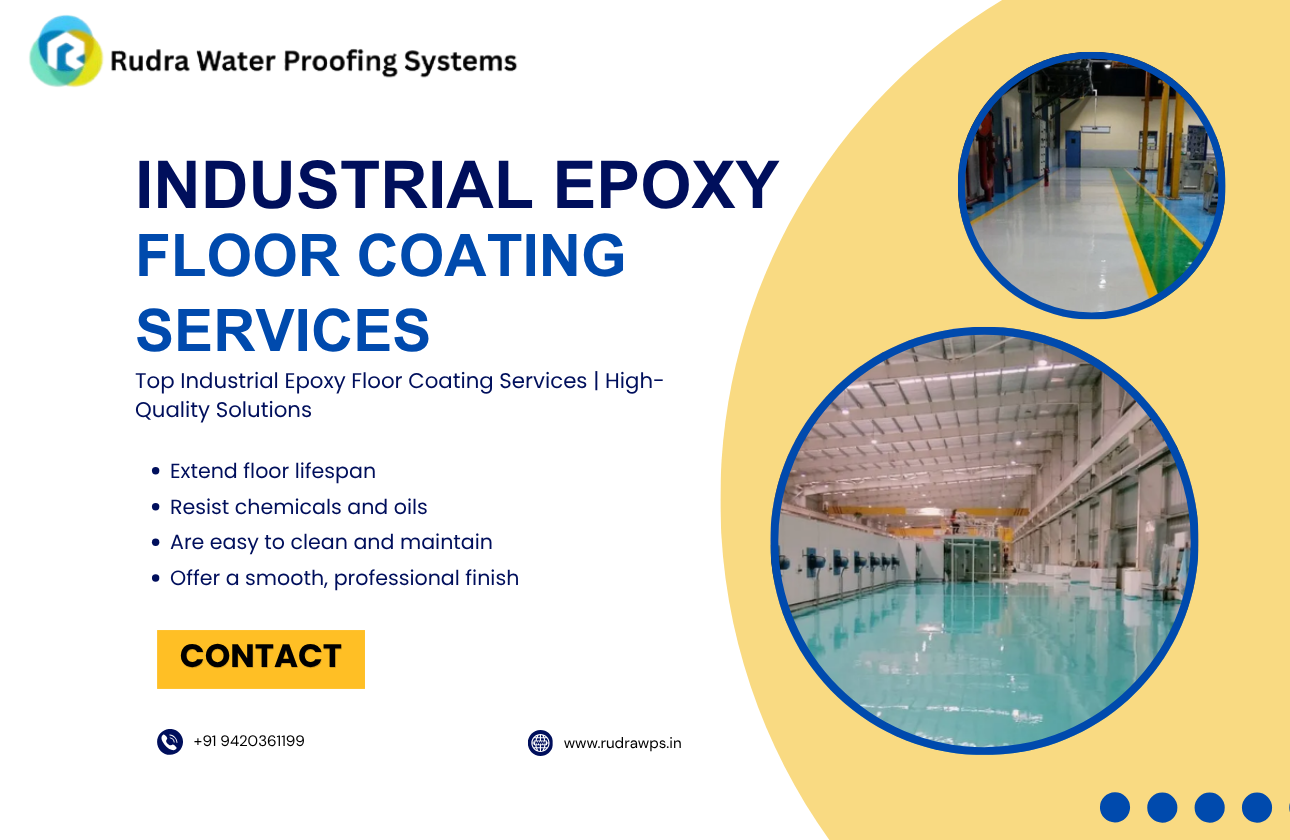

At Rudra Water Proofing Solutions (Rudra WPS), we provide specialized Industrial Epoxy Floor Coating Services designed to deliver long-term durability, easy maintenance, and superior safety.

Our epoxy flooring systems not only protect your concrete floors but also enhance your workspace’s appearance and functionality — making them ideal for factories, warehouses, production plants, and workshops.

What is Industrial Epoxy Floor Coating?

Industrial Epoxy Floor Coating is a high-performance protective system made from a blend of epoxy resin and a hardener. When applied to concrete, it forms a strong, seamless, and glossy surface that is resistant to wear, abrasion, and chemicals.

Epoxy coatings are ideal for industrial environments because they:

- Extend floor lifespan

- Resist chemicals and oils

- Are easy to clean and maintain

- Offer a smooth, professional finish

- Enhance workplace safety

At Rudra WPS, our epoxy coating experts customize every project according to your facility’s requirements — whether you need anti-slip, chemical-resistant, or heavy-duty epoxy coatings.

Why Choose Rudra WPS for Industrial Epoxy Floor Coating Service?

Rudra WPS is one of the most trusted providers of industrial epoxy coating and waterproofing services in India. Here’s why industries prefer us:

1. Professional Expertise

With years of experience and advanced tools, Rudra WPS ensures precise application, strong bonding, and long-lasting performance in every epoxy floor coating project.

2. Premium-Quality Materials

We use only industrial-grade epoxy resins and hardeners sourced from leading brands to deliver coatings that resist abrasion, heat, and chemicals.

3. Tailored Coating Solutions

From light-duty workshops to heavy machinery floors, we offer custom epoxy flooring systems suited for different industrial environments.

4. Safety & Aesthetics Combined

Our coatings not only protect your floor but also improve visibility and cleanliness, ensuring safe and visually appealing workspaces.

5. Cost-Effective & Long-Term Investment

Epoxy coatings reduce repair costs and extend the lifespan of your flooring — providing a high return on investment for every business.

Key Benefits of Industrial Epoxy Floor Coating Services

1. Exceptional Durability

Epoxy floors can handle heavy loads, forklifts, and continuous operations without cracking or peeling.

2. Chemical Resistance

Industrial facilities often deal with oils, solvents, and acids. Our epoxy coatings protect your concrete from chemical corrosion and staining.

3. Low Maintenance

Epoxy floors are non-porous, so they don’t absorb dirt or water. Simple mopping keeps them clean and shiny.

4. Slip-Resistant & Safe

We offer anti-slip textures and safety markings to reduce workplace accidents and improve operational flow.

5. Enhanced Aesthetic Appeal

A clean, glossy floor boosts morale and reflects professionalism. You can even choose from multiple colors and finishes.

6. Hygienic & Dust-Free

Epoxy coatings prevent dust formation from concrete and are ideal for industries with hygiene requirements like pharma, food, and electronics.

Our Industrial Epoxy Floor Coating Process

To ensure quality and consistency, Rudra WPS follows a step-by-step coating process for all industrial flooring projects:

- Surface Preparation:

We begin by cleaning and grinding the surface to remove dirt, oil, and old paint. Proper preparation ensures strong epoxy adhesion.

- Crack Repair & Leveling:

Any cracks or uneven areas are repaired to create a smooth, uniform base.

- Primer Coat Application:

A primer layer is applied to seal the surface and improve bonding.

- Epoxy Coating Application:

The epoxy resin and hardener mixture is applied in multiple layers using rollers or trowels for even coverage.

- Curing & Finishing:

The floor is allowed to cure properly to achieve maximum strength, shine, and durability.

- Final Inspection:

Our experts inspect the coated area for perfection before handing it over to the client.

Applications of Industrial Epoxy Floor Coating

Our Industrial Epoxy Floor Coating Services are suitable for a wide range of environments, including:

- Manufacturing Plants & Factories

- Automotive Workshops & Garages

- Warehouses & Storage Facilities

- Chemical & Pharmaceutical Units

- Food Processing Units

- Cleanrooms & Laboratories

- Engineering & Fabrication Units

Each site is analyzed by our technical team to ensure the most efficient and durable epoxy coating solution is applied.

Why Industrial Epoxy Coating is Better than Conventional Flooring

| Feature | Epoxy Coating | Concrete/Tile Flooring |

| Durability | 10–15 Years | 3–5 Years |

| Maintenance | Minimal | Frequent Repairs |

| Chemical Resistance | Excellent | Poor |

| Appearance | Glossy & Modern | Dull & Uneven |

| Cost Efficiency | High ROI | Average ROI |

Why Businesses Trust Rudra WPS

At Rudra Water Proofing Solutions, quality and reliability are our foundation. We’ve successfully delivered industrial epoxy flooring projects across multiple sectors, earning a reputation for precision, consistency, and durability.

We don’t just apply coatings — we build surfaces that stand strong against the toughest conditions, ensuring your industrial floors are safe, efficient, and maintenance-free for years.

FAQs

1. How long does an epoxy floor coating last in industrial use?

An epoxy floor installed by Rudra WPS typically lasts 10 to 15 years, depending on the type of industry, surface preparation, and maintenance routine.

2. Can epoxy coating be applied over old concrete floors?

Yes. Our team prepares the old concrete by grinding and cleaning before applying the epoxy, ensuring strong adhesion and smooth results.

3. Is epoxy flooring suitable for heavy machinery and chemical exposure?

Absolutely! Industrial epoxy coatings are chemical-resistant and load-bearing, perfect for factories, warehouses, and mechanical workshops.

Build Strong Foundations with Rudra WPS

A well-coated industrial floor is more than a surface — it’s a foundation for safety, performance, and longevity.

At Rudra WPS, our Industrial Epoxy Floor Coating Services provide unmatched durability, resistance, and visual appeal for any industrial setup.

Visit: https://www.rudrawps.in/epoxy-floor-coating-services.php

Contact: +91 9420361199

Published on October 13, 2025 by Admin