High-Quality Cipoxy Epoxy Coatings for Industrial and Commercial Protection

When it comes to surface protection and long-term performance, Cipoxy Epoxy coatings have become a trusted solution across multiple industries. Known for their durability, excellent adhesion, and chemical resistance, these coatings protect metal and concrete surfaces against corrosion, wear, and environmental damage.

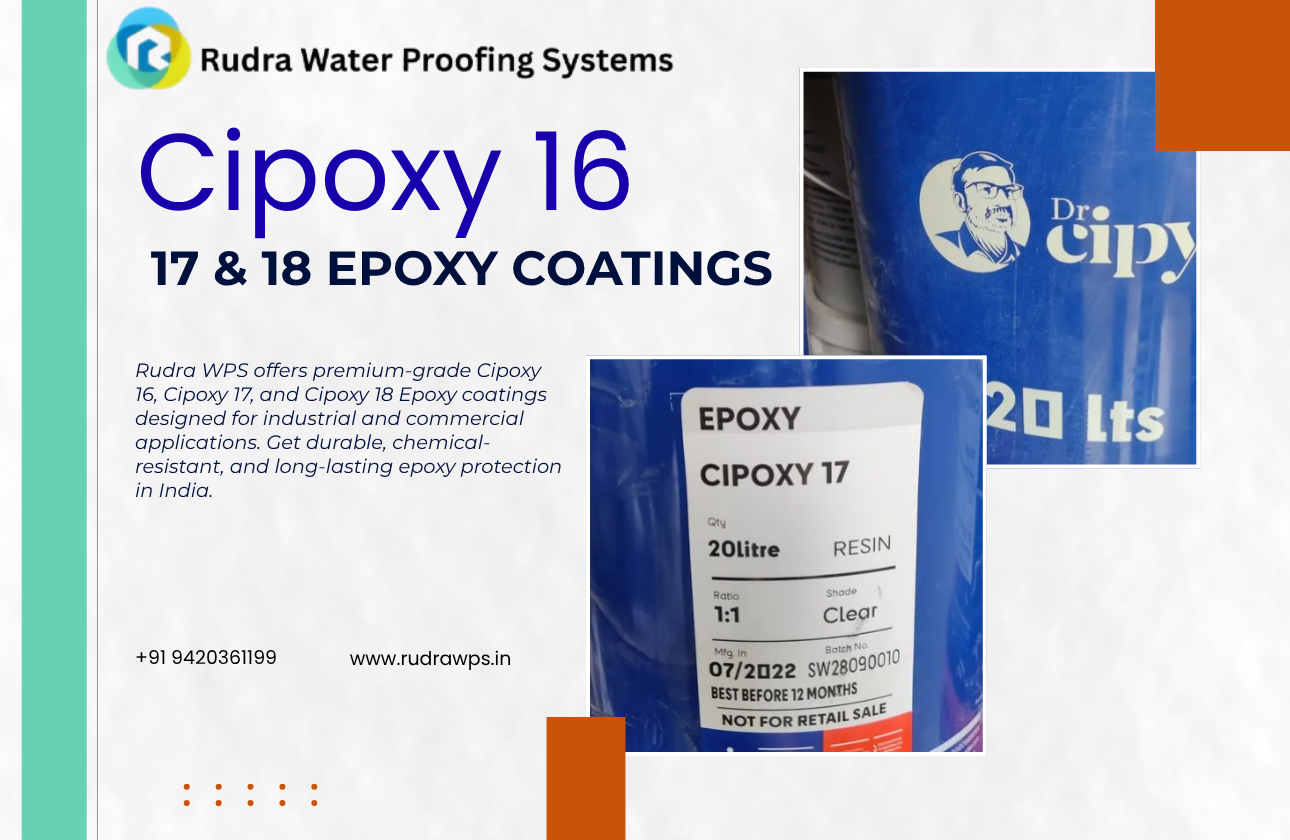

At Rudra WPS, we manufacture and supply premium-quality Cipoxy Epoxy coatings—including Cipoxy 16 Epoxy, Cipoxy 17 Epoxy, and Cipoxy 18 Epoxy—designed to meet industrial-grade standards. Our epoxy products are formulated with high solids and superior resin systems, offering an ideal balance of protection and aesthetic appeal.

What Is Cipoxy Epoxy?

Cipoxy Epoxy is a high-performance, two-component coating system that provides exceptional protection against corrosion, chemicals, and abrasion. It is widely used in sectors such as industrial flooring, chemical plants, machinery coating, and infrastructure development.

Rudra WPS’s Cipoxy series includes the following variants:

- Cipoxy 16 Epoxy:

A general-purpose epoxy coating designed for moderate environmental conditions and protective applications.

- Cipoxy 17 Epoxy:

A heavy-duty epoxy coating ideal for industrial use, offering superior resistance to chemicals, moisture, and abrasion.

- Cipoxy 18 Epoxy:

A premium-grade epoxy coating engineered for extreme environments requiring high chemical resistance and long-lasting performance.

Each variant is formulated with precision to deliver consistent, reliable results that extend the lifespan of surfaces.

Key Features and Advantages

1. Excellent Corrosion Resistance:

Cipoxy Epoxy coatings protect metal surfaces from oxidation and rust, ensuring structural integrity and durability.

2. Superior Adhesion:

The advanced epoxy resin system ensures excellent bonding with concrete, steel, and other substrates.

3. High Gloss Finish:

Offers a smooth, attractive finish that enhances aesthetics while providing a protective barrier.

4. Chemical and Abrasion Resistance:

Resists damage from industrial chemicals, solvents, oils, and mechanical stress.

5. Easy Application and Maintenance:

Can be applied by brush, roller, or spray, and requires minimal upkeep once cured.

6. Long-Term Durability:

Ensures extended service life even in harsh industrial environments.

Applications of Cipoxy Epoxy Coatings

Rudra WPS’s Cipoxy Epoxy coatings are suitable for a wide range of industrial and commercial applications, including:

- Industrial floors and machinery coatings

- Pipelines, tanks, and vessels

- Chemical and fertilizer industries

- Power plants and marine structures

- Workshops, garages, and warehouses

- Bridges, cranes, and heavy equipment

Each product in the Cipoxy range offers unmatched protection, ensuring that surfaces remain durable, clean, and corrosion-free.

Why Choose Rudra WPS for Cipoxy Epoxy Coatings?

As one of the leading manufacturers and suppliers of epoxy coatings in India, Rudra WPS is dedicated to quality, innovation, and performance.

Here’s why clients across industries trust us:

Advanced Formulations: We use premium-grade resins and curing agents for superior performance.

Custom Solutions: Available in multiple grades to suit specific industrial requirements.

Quality Assurance: Each batch is rigorously tested for consistency and durability.

Eco-Friendly Manufacturing: Formulated with low-VOC components, ensuring worker and environmental safety.

Expert Support: Technical guidance for application, product selection, and maintenance.

When you choose Rudra WPS, you’re investing in coating technology that ensures reliability, longevity, and superior protection.

Technical Benefits of Cipoxy 16, 17, and 18 Epoxy

Rudra WPS’s Cipoxy series offers a perfect blend of functionality and protection. Some of the technical advantages include:

- High solids content ensures thick, protective coating layers.

- Resistance to moisture, acids, alkalis, and solvents.

- Suitable for both indoor and outdoor environments.

- Excellent mechanical strength and impact resistance.

- Fast drying and easy re-coatability for efficient project completion.

These benefits make Cipoxy coatings ideal for industries demanding robust, long-term performance under challenging conditions.

Application Guidelines

For the best results, proper application techniques are essential:

- Surface Preparation:

Ensure the surface is clean, dry, and free from oil, grease, or rust.

- Mixing:

Mix base and hardener in the recommended ratio to achieve a uniform blend.

- Application:

Apply evenly with a brush, roller, or spray gun for smooth coverage.

- Curing:

Allow sufficient drying and curing time between coats for optimum performance.

Following these steps guarantees a long-lasting, glossy finish and maximum protection.

Whether you need protection for industrial flooring, heavy machinery, or metal structures, Rudra WPS Cipoxy Epoxy coatings deliver unmatched results.

Our Cipoxy 16, 17, and 18 epoxy variants are engineered to perform in the most demanding conditions—offering resistance, durability, and a flawless finish.

Choose Rudra WPS, one of India’s most trusted Cipoxy Epoxy manufacturers and suppliers, for advanced surface protection solutions that last.

(FAQs)

Q1. What is the difference between Cipoxy 16, 17, and 18 Epoxy?

Cipoxy 16 is a general-purpose coating, Cipoxy 17 is ideal for heavy-duty industrial use, and Cipoxy 18 is designed for extreme chemical and environmental resistance.

Q2. Can Cipoxy Epoxy coatings be used on concrete floors?

Yes, Cipoxy coatings are excellent for concrete flooring in factories, warehouses, and workshops, providing durability and easy maintenance.

Q3. How long do Cipoxy Epoxy coatings last?

With proper surface preparation and application, Cipoxy coatings can last 5–10 years or more, depending on usage and exposure conditions.

Visit: https://www.rudrawps.in/20-ltr-cipoxy-17-epoxy.php

Contact: +91 9420361199

Published on October 13, 2025 by Admin